Pentho Control

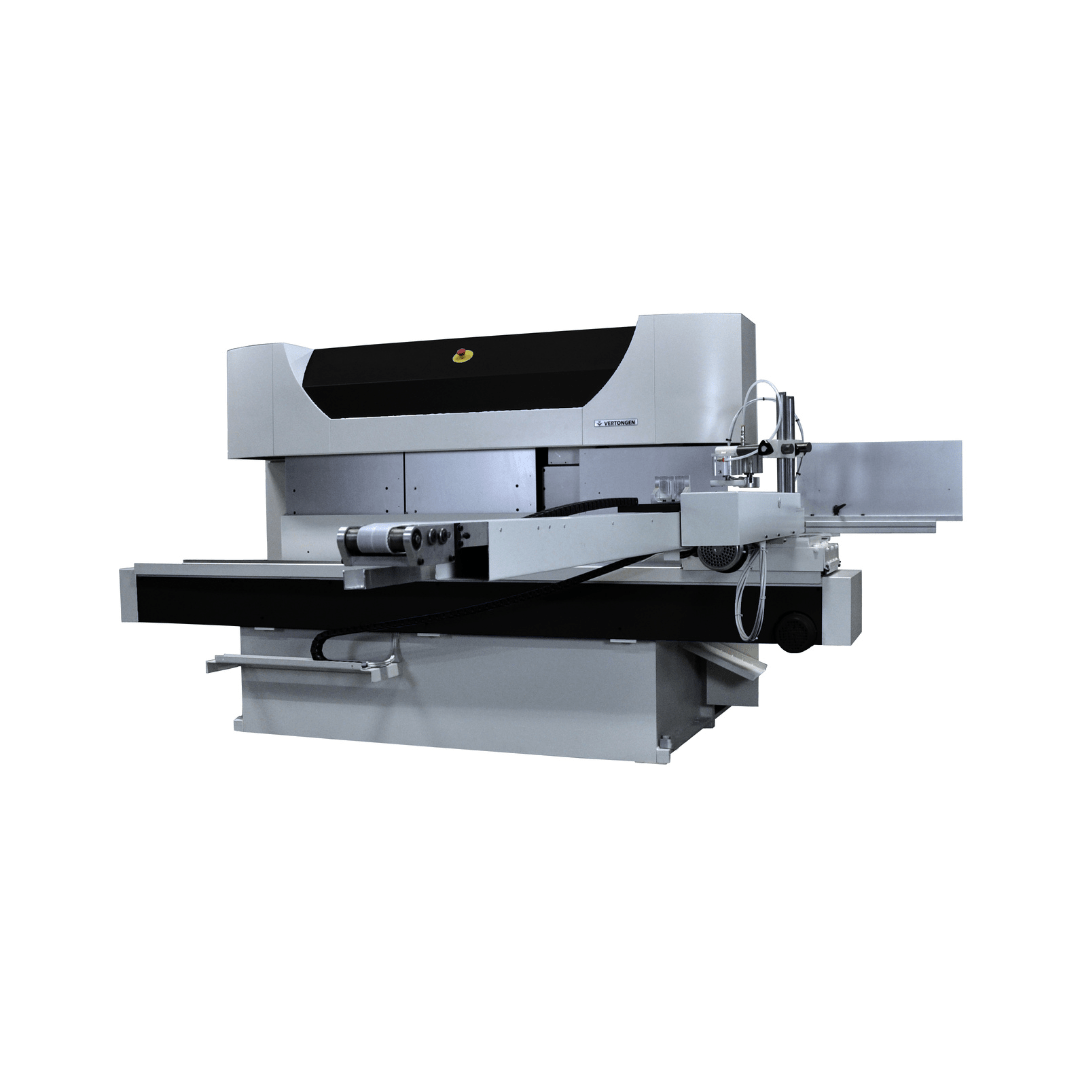

The Pentho Control is produced with one or more vertical spindles and a noise-reduced cut-off saw.

- Saw with cut-off capacity 200 mm

- One or more vertical spindle(s) 300mm or 545mm

- 7 inch touch panel in own language

- Composition depending on customer needs

- Total project followed by Vertongen

- CNC available on every movement

- Combinable with profile moulder

- Online communication available

The Pentho Control has one or more vertical spindles and a noise-reduced cut-off saw.

All spindles and features can be combined with each other. For angled work, the solid table can be swivelled 45° in two directions.

The Pentho Control incorporates an extension to the touch screen control. This makes storing and recalling machine settings very easy, saving you a lot of time during the setup process.

Another great advantage to the Pentho Control is its modularity. Two main options are available: pneumatic clams, and an automatic table and an automatic length stop. This allows the basic functionality of the machine to be adapted to the specific needs of the operator. Making the Pentho Control a more flexible and versatile machine.

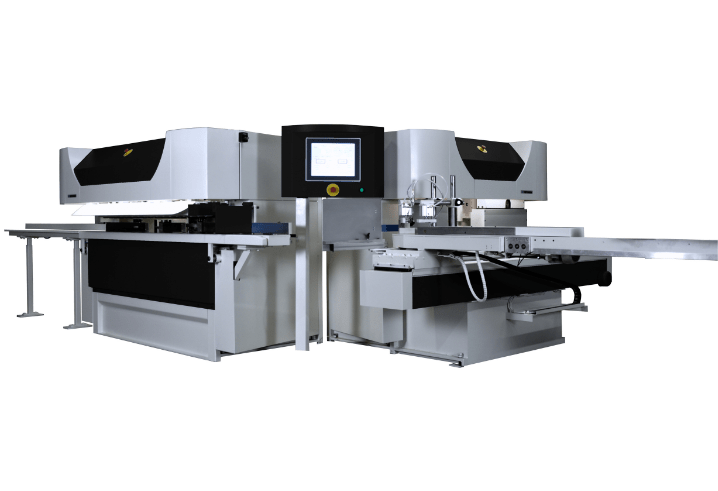

The Pentho Control can be entirely automated and be combined with a “Profil Control” in order to come to a complete window line.

VERTONGEN TIP!

The Pentho Control can be entirely automated and be combined with the Profil Control to come to a complete window line.

Technical product specifications

General

- 7 inch touch panel:

- Operate the machine and select motors

- Safety standards:

- Conform CE

- Safety screen:

- Pneumatic aluminium protection plates

- Construction:

- Combined self-supporting frame with a cage construction

Table

- Table mounting:

- Horizontal on rails, extra solid

- Movement:

- Manual with automatic movement option

- Table:

- Fixed in height, Swivelling +45° to -45°

- Backing wood:

- Round backing wood with 4 manual positions, clamp for

straight backing wood; pneumatic backing wood option - Clamps:

- 2 vertical pneumatic clamps

- Length fence:

- 2,4m, with 3,4m and automatic length-fence option

- Dimensions:

- 160mm x 1000mm

Cut-off saw

- Motor:

- 2,2 kW - 3000 tpm

- Adjustment:

- Horizontal 150mm, with cut-off capacity up to 200mm

- Noise reduced saw:

- Ø 450mm, included

- Extraction:

- Ø 80mm

- Positioning:

- Manual with digital read-out or CNC option

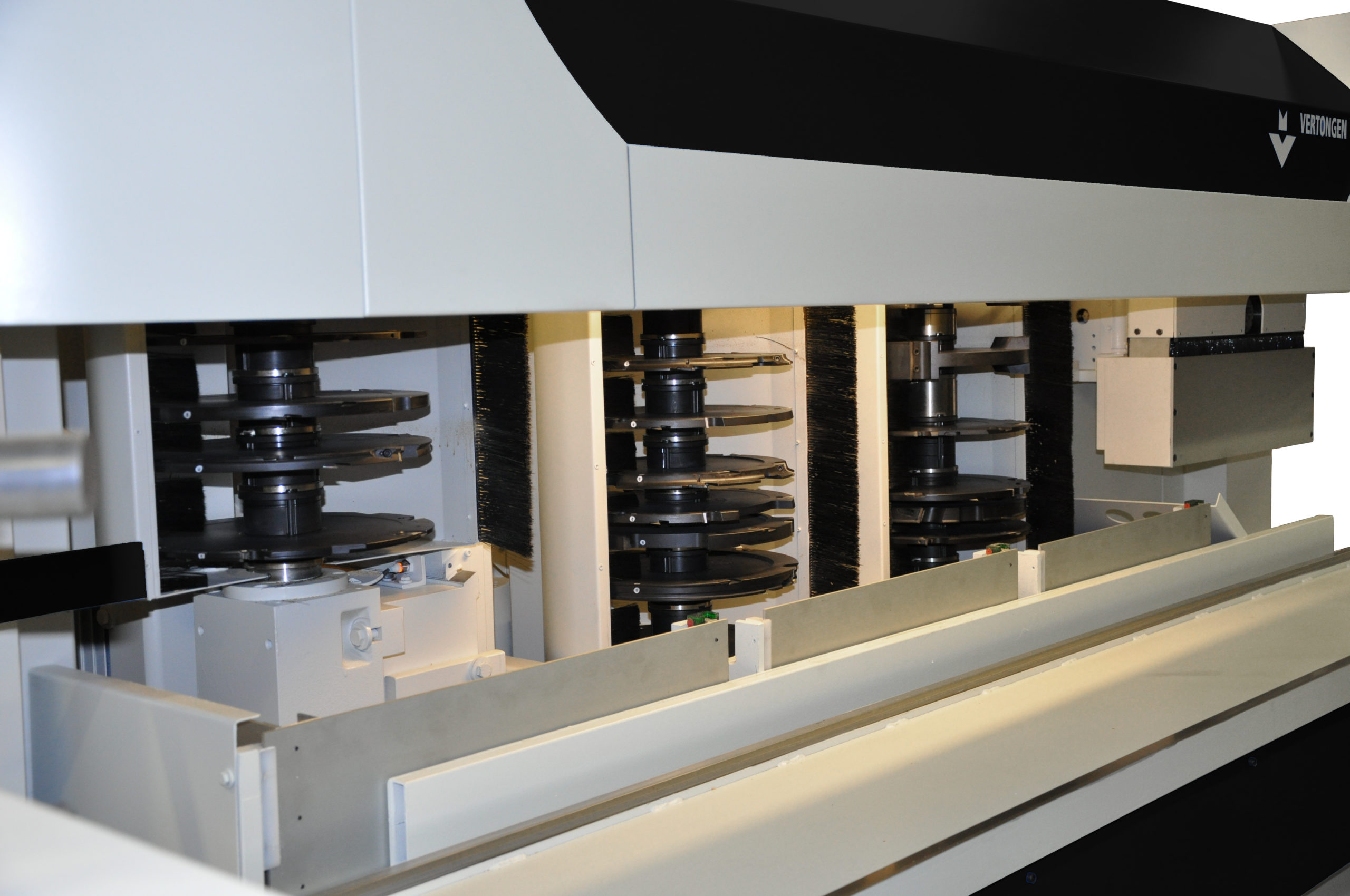

Vertical spindle

- Motor:

- 11 kW

- RPM:

- 4000 tpm

- Suspension:

- Dovetailed

- Movement:

- Vertical 0mm to 500mm

- Positioning:

- Vertical CNC-positioned wit ball circulating screw

Horizontal fix: on/off or CNC-positioned option - Measurements spindle(s):

- Length: 300mm with Prolock or 545mm with top bearing

Diameter: Ø 50mm - Spindle Ø:

- Ø 50 mm

- Tool Ø:

- Maximum Ø 350mm

- Extraction:

- Ø 180 mm

Extra options

- Extra options:

- 15 inch touch panel with separate control console

Automatic length-fence

You may also be interested in

Profil Control

The Profil Control is produced with one or more spindles.

- 7″ touch panel in own language

- Composition depending on customer needs

- Total project followed by Vertongen

- CNC available on every movement

- Combinable with tenoner

- Online communication available

PenPro Control

The Penpro Control is a fully CNC-controlled combination of the Pentho Control and the Profil Control.

- One-man operation

- Production capacity of more than 400 parts each shift

- 15″ touch panel in own language

- Mounting of the tools and presetting the machine done by Vertongen

- Total project followed by Vertongen

Please fill out the form below and you will receive a link via email to download our brochure.

Find a Vertongen dealer

Vertongen is a Belgium-based company with distributors all over the world. All of them are knowledgeable about the operation and use of our machines.

Want to know more about Vertongen, our machines, how they work, and how to implement them into your operations?

Contact us and get ready to revolutionize your production process or contact a local supplier.